.png?v=v1)

.png?v=v1)

2023.02.23

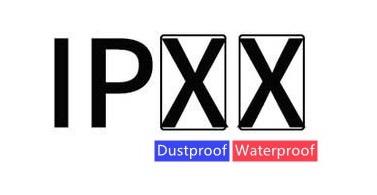

IP protection system is to classify electrical appliances according to their characteristics of dust and moisture prevention. It refers to what environmental conditions electrical equipment is suitable for (such as instruments, lighting equipment, installation materials) and how to protect users from potential hazards. For the adaptability of different environments, the IP protection degree standard has divided corresponding IP codes. IP protection degree is composed of two numbers.

The first number indicates the degree of protection against contact and the entry of solid foreign objects. The following table describes the meaning of the first digit of the IP degree:

Digit | Degree of protection against physical contact | Protection degree of solid foreign objects |

0 | Unprotected | Unprotected |

1 | Prevent large part of human body from entering (diameter 50mm) | Prevent large solid foreign objects from entering (diameter ≥ 50mm) |

2 | Finger entry prevention (diameter 12mm) | Prevent medium-size solid foreign objects from entering (diameter ≥ 12.5mm, length ≤ 80mm) |

3 | Prevent tools and metal wires from entering (diameter ≥ 2.5mm) | Prevent small solid foreign objects from entering (diameter ≤ 2.5mm) |

4 | Prevent tools, wire and fine wire from entering the diameter ≥1mm) | Prevent the entry of solid particles and foreign matters (diameter ≤ 1mm) |

5 | Wire protection (like IP4), dust protection | Dust accumulation (harmless) |

6 | Wire protection (like IP4), dust protection | Dust cannot enter |

The second digit indicates the degree of protection against liquids. The following table describes the meaning of the second number of IP code.

Digit | Waterproof protection |

0 | Unprotected |

1 | Protection against vertical dripping |

2 | Protection against direct splashing water within 15 degrees from the vertical direction |

3 | Protection against direct splashing water within 60 degrees from the vertical direction |

4 | Protection against spray water in any direction |

4k | It has protection against pressurized spray water in any direction, and only applies to road vehicles |

5 | Protection against low pressure jet water in any direction |

6 | Protection against huge waves or strong jet water (water injection) |

6k | It has protection (water injection) against pressurized strong jet water, and only applies to road vehicles |

7 | Protection against short immersion in water |

8 | Protection against long-term immersion in water |

9k | Protects against high-pressure steam injection, only for road vehicles |

Note: Each protection level should be considered separately. High protection level does not automatically have low protection level.

Introduction to IP protection test

1. Scope

Waterproof test includes * * with characteristic numbers of 1 to 8, i.e. protection degree code of IPX1 to IPX8

2. Waterproof test contents of various degree

(1) IPX1

Method name: vertical drip test

Test equipment: drip test device and its test method

Sample placement: place the sample on a rotating table with a speed of 1 r/min according to its normal working position, and the distance from the top of the sample to the drip opening is not more than 200 mm

Test conditions: the water drop is 1.0+0.5 mm/min;

Test duration: 10min

(2) IPX2

Method name: inclined 15 ° drip test

Test equipment: drip test device and its test method

Sample placement: make one side of the sample form an angle of 15 ° with the vertical line, and the distance from the top of the sample to the drip opening is not more than 200 mm. After each side is tested, change the other side for four times

Test conditions: the water drip is 3.0+0.5 mm/min;

Test duration: 4 × 2.5 min, 10 min in total

(3) IPX3

Method name: rain test

A. Pendulum type water spraying test

Test equipment: Pendulum type water spray test

Sample placement: select a pendulum tube with appropriate radius, make the height of the sample table at the position of the diameter of the pendulum tube, place the sample on the sample table, make the distance from its top to the sample spray nozzle not more than 200mm, and the sample table does not rotate.

Test conditions: water flow is calculated according to the number of spray holes in the swing pipe, and each hole is 0.07L/min. When spraying water, the water from the spray hole in the 60 ° arc section on both sides of the midpoint of the swing pipe is sprayed to the sample. Place the sample at the center of the semicircle of the pendulum tube. The swing tube swings 60 ° along both sides of the vertical line, a total of 120 °. Each swing (2 × 120 °) for about 4s.

Test pressure: 400kPa;

Test time: continuous watering for 10min; The sample rotates 90 ° after 5 min of test

B. Sprinkler type water spraying test

Test equipment: hand-held water spraying and splashing test device,

Sample placement: make the parallel distance from the top of the test to the handheld nozzle between 300mm and 500mm

Test conditions: baffle with balance weight shall be installed during the test, and the water flow is 10L/min

Test time: 1min per square meter (excluding the installation area), * 5min less, calculated according to the surface area of the tested sample housing.

(4) IPX4

Method name: splash test;

A. Pendulum type splash test

Test equipment and sample placement: select a pendulum tube with appropriate radius, make the height of the sample table at the position of the diameter of the pendulum tube, place the sample on the sample table, make the distance from its top to the sample spray nozzle not more than 200mm, and the sample table does not rotate.

Test conditions: water flow is calculated according to the number of spray holes in the swing pipe, and each hole is 0.07L/min; The water spray area is the water spray hole in the 90 ° arc section on both sides of the midpoint of the swing pipe. Place the sample at the center of the semicircle of the pendulum tube. The swing tube swings 180 ° along both sides of the vertical line, about 360 ° in total. Each swing (2 × 360 °) for about 12s.

Test time: the same as that in Clause a of IPX3 in Clause (3) above (i.e. 10min).

B. Nozzle type splash test

Test equipment: hand-held water spraying and splashing test device,

Sample placement: the baffle with counterweight installed on the equipment shall be removed so that the parallel distance from the top of the test to the spray nozzle of the handheld nozzle is between 300mm and 500mm.

Test conditions: baffle with balance weight shall be installed during the test, and the water flow is 10L/min.

Test time: it is 1min per square meter (excluding the installation area) * 5min less, calculated according to the surface area of the tested sample housing.

(5) IPX4K

Test name: pressurized pendulum tube rain test

Test equipment: pendulum tube rain test

Sample placement: select a pendulum tube with appropriate radius, make the height of the sample table at the position of the diameter of the pendulum tube, place the sample on the sample table, make the distance from its top to the sample spray nozzle not more than 200mm, and the sample table does not rotate.

Test conditions: water flow is calculated according to the number of spray holes in the swing pipe, and each hole is 0.6 ± 0.5L/min. The water spray area is the water spray hole in the 90 ° arc section on both sides of the midpoint of the swing pipe. Place the sample at the center of the semicircle of the pendulum tube. The swing tube swings 180 ° along both sides of the vertical line, about 360 ° in total. Each swing (2 × 360 °) for about 12s.

Test pressure: 400kPa

Test time: sample rotates 90 ° after 5 min of test

Note: The spray pipe has 121 holes with diameter of 0.5mm;

--1 hole in the center

--2 layers of core area (12 holes in each layer, distributed at 30 degrees)

--4 outer rings (24 holes per ring, 15 degree distribution);

--Removable cover.

The spray pipe shall be made of copper zinc alloy (brass).

(6) IPX5

Method name: water spray test

Test equipment: inner diameter of spray nozzle is 6.3mm

Test conditions: the distance between the test sample and the water spray nozzle is 2.5~3m, and the water flow is 12.5 L/min (750 L/h);

Test time: 1min per square meter (excluding the installation area) * 3min less, calculated according to the surface area of the shell of the tested sample.

(7) IPX6

Method name: strong water spray test;

Test equipment: the inner diameter of the spray nozzle is 12.5mm;

Test conditions: the distance between the test sample and the water spray nozzle is 2.5~3m, and the water flow is 100L/min (6000L/h);

Test time: 1min per square meter (excluding the installation area) * 3min less, calculated according to the surface area of the shell of the tested sample.

D=6.3mm waterproof protection grade 5 and 6K;

D=12.5mm waterproof protection grade 6.

(8) IPX7

Method name: short-term immersion test;

Test equipment: immersion tank.

Test conditions: the size shall be such that the distance from the bottom of the sample to the water surface is at least 1m after the sample is put into the immersion tank. The distance from the top of the sample to the water surface shall be at least 0.15m. Test time: 30min.

(9) IPX8

Method name: continuous diving test;

Test conditions and test time of test equipment: to be agreed by both parties. The severity shall be higher than IPX7.

(10) IPX9K

Method name: high-pressure injection test

Test equipment: the inner diameter of the spray nozzle is 12.5mm;

Test conditions: water spray angle: 0 °, 30 °, 60 °, 90 ° (4 positions); Number of spray holes: 4; Rotating speed of sample table: 5 ± 1 r.p.m; The distance is 100~150 mm, and each position is 30 seconds; The flow is 14~16L/min, and the water spray pressure is 8000~

10000kPa, water temperature requirement 80 ± 5 ℃

Test time: 30 seconds at each position × 4 120 seconds in total.

In industrial production, the enclosure protection degree of automatic instrument equipment is an important indicator to ensure the normal operation of equipment and the safety and reliability of the products. During the purchase process, you can confirm the product parameters with us. For example, our conventional power instruments are high-precision and highly reliable intelligent power distribution instrument products designed for power system, industrial and mining enterprises, public facilities, smart buildings and other applications of power monitoring, intelligent control, measurement and assessment. The panel protection level is generally IP54 and some panel mount power quality analyzer can reach IP64 for its front panel. Such as Elecnova digital power analyzer Sfere720, which can fulfil variety request for the industrial and commercial applications.

Copyright © 2019.Company Name All Rights Reserved.