.png?v=v1)

.png?v=v1)

2022.06.27

In the era of rapid digitalization, there is a superhuman presence in the field of motor control and protection. In the past years, they have replaced the thermal relay, time relay, transmitter and other electrical components, optimized the conventional motor protection and control scheme, with a wider protection range, more accurate and reliable action values, and more intuitive and rapid troubleshooting in case of failure, so as to take good care of our Asynchronous motors.

Elecnova WDH-31 series motor protection controller has been playing an important role in the field of electrical equipment to protect the safe operation of equipment.

WDH- 31- 530 series motor protection controller (hereinafter referred to as the motor controller) is suitable for three-phase low-voltage AC motor applications with rated frequency of 50/60hz, rated voltage of 690V AC and rated current up to 800A. The product has the functions of monitoring, control, protection and communication, and provides perfect protection and control for electric machines. The motor controller consists of three parts: the main body, the protective current transformer module and the HMI; The controller body and the transformer are fixed and used as a whole.

WDH-31-200 motor protection replay can replace the thermal relay, transmitter and other electrical components, simplify the traditional motor control and protection, with wider protection range, more accurate and reliable action, and more intuitive troubleshooting in case of failure, which can help customers quickly judge the cause of failure and reduce economic losses.

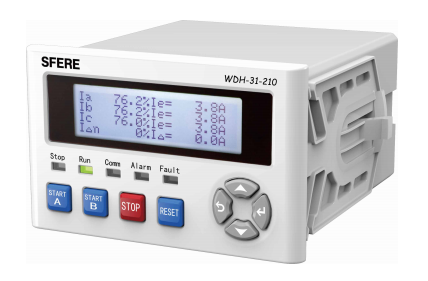

WDH-31-210 motor protection relay can support 5 circuits programmable switch input (dry contact) and 4 circuits programmable relay output. All input and output have programmable functions to meet different protection control requirements on site. All protection functions can set alarm values and operating values at the same time, and can be switched on and off respectively. The protection parameters can be set by professionals according to the actual working conditions of the on-site, after setting it will not be lost when power off.

WDH-31-500 motor protection controller can provide up to 12 circuits of programmable switch inputs (dry/wet contacts are optional) and 7 circuits of programmable relay output. All input and output have programmable functions to meet different on-site protection control requirements. All protection functions can set alarm values and action values at the same time, and can be switched on and off respectively. The protection parameters can be set by professionals according to the actual working conditions of the motor on site setting, it will not be lost when power off.

WDH-31-580 motor protection and management system can provide up to 12 circuits of programmable switch inputs (dry/wet contact optional), and 8 circuits of programmable relay output. All input and output have programmable functions to meet different on-site protection control requirements. All protection functions can set alarm values and action values at the same time, and can be switched on and off respectively. The protection parameters can be set by professionals according to the actual working conditions of the motor on site setting, it will not be lost when power off.

Copyright © 2019.Company Name All Rights Reserved.